Know about the backend operations of pre-engineered buildings !

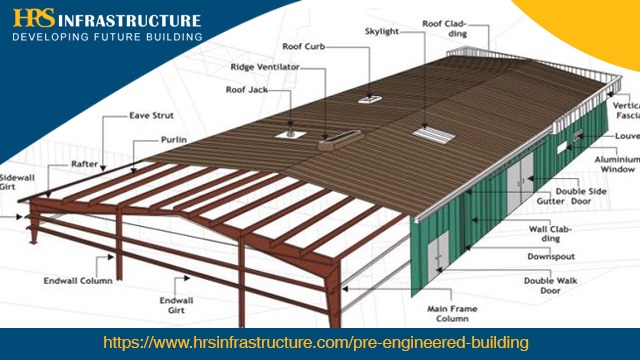

As we already know, pre-engineered buildings are essentially steel constructions that are designed distinctively and are made-up to meet the client’s requirements. They are constructed in harmony with the widespread ethics and involve different constituents which are mainly designed in such a way that makes them compatible with each other.

This type of construction has become a flexible answer for contractors and owners who require the structure to be built in a short period of time. Due to their growing fame, pre engineered buildings are used as warehouses, factories, showrooms, and as well as shopping malls.

In order to understand the concept of pre-engineered buildings, you must understand the following things as well:

Design

The steel frames that are mandatory to be used in a precise erection is first of all designed and fabricated at the factory site itself. The method of designing the PEB structures is not that easy and is done with the help of software through computer supported designs. The structure is designed under the administration of specialists so that there is no scope of error in the initial step.

Foundation

Once the design has been finalized of the steel structures, the next step is to lay the foundation.

This fundamentally includes the practice of clearing the site as well as building a solid foundation. Since PEB structures are lightweight as compared to the normal structures, therefore, shallow isolated foundations are chosen for the purpose of construction. Pile foundation is preferred in the areas that are prone to natural calamities like landslides or earthquakes so it gives the structure more strength.

Installation

Once the foundation is laid, the next step that takes place is the creation of steel frames. The quality of steel that is used for framing is majorly based on the structural requirements. For example, let us say that the structure is of one floor then the size of the frame will be between 0.9 mm to 1.2 mm. However, for a 2 level warehouse or building, the breadth of the structure should be more than 4mm.

Construction of the walls

The last step is the construction of the walls of pre engineered buildings manufacturers. The walls for PEB houses are built using a diversity of materials that includes granite, cement, stone and bricks. The type of the material that is chosen for the construction of walls depends upon the preference of the client. Even though walls are constructed using a number of materials, insulated steel panels are favored mostly over another type of material due to their physical steadiness.

The flooring system

In the pre-engineered buildings, the flooring system that is used is the Mezzanine Flooring System.

A mezzanine floor is an intermediary floor between main floors of a pre-engineered building and therefore it is not counted as overall floors of a building.

Usually, the mezzanine structure is associated with the main rigid frame columns for adjacent firmness. This mezzanine framing comprises profiled steel deck, beams, joists, and intermediate support columns.

The mezzanine system in a warehouse successfully increases the capability of the area where the mezzanine floor is constructed. Some of the Mezzanine is built to house light apparatus and office space, while some are used for temporary or long-term storage of provisions or tools.

These can be built in square, rectangular and irregularly-shaped formations.

They can be mechanical as they can be built into the structure of a building.

Mezzanines surface are often nettled and they are typically much smaller in terms of area than the stories below them.

If you would like to know anything else about the pre-engineered buildings then feel free to get in touch with us and we will guide you in the best possible way with our expertise and knowledge in the field.

our pursuit to achieve excellence, we are counted amongst as the prime PEB Manufacturers, traders, and PEB Suppliers of an excellent quality assortment of Pre Engineered Building Systems which is used as factory workshops and warehouses. Appreciated by our clients for features like high strength, robust construction and rust proof surface finish these systems are acknowledged all around the market. The offered systems are designed and fabricated using sound wooden, aluminum, steel and other allied materials in accordance with the international quality standards. These Pre Engineered Building Systems are assembled as per the latest designs and are well-suited for modern industries.

ReplyDeleteweebly seo

ReplyDeletethực đơn giảm cân

I am so greatfull for your blog VISIT HERE PEB Manufacturers

ReplyDeleteNice Blog. Thank u for sharing your information. Willus Infrastructure was founded in 2017, and our warehouse is equipped with premium-quality materials and advanced procedures. We are India's top Warehouse Manufacturers. Our warehouse is not only very strong and resistant, but also extremely attractive and durable, and it is extensively utilized in a variety of industries, including cold storage, go downs, agricultural regions, and so on.

ReplyDelete